As website Gizmodo reports, environmental and moral concerns are encouraging a growing number of people to push for substituting cultured meat for traditional meat.

As more people examine these issues, scientists look even more closely at how to turn lab-grown meat into a feasible alternative.

Check This Out…

The meat industry is a huge contributor to humanity’s environmental footprint, accounting for some 18% of our total greenhouse gas emissions. And that number’s deceptively low, because it includes roughly 40% of methane and 65% of nitrous oxide emissions, which are respectively 23 and nearly 300 times more potent climate warming agents than carbon dioxide. What’s more, the environmental footprint of livestock production is growing fast. By 2050, global meat production is projected to double from its 1999 levels, according to the FAO. At that time, the FAO writes, “The environmental impact per unit livestock must be cut by half, just to avoid increasing the level of damage beyond its present level.”

If climate arguments aren’t your MO, try this one on for size: Animal agriculture is soaking up an enormous portion of our arable land, drinkable water, edible food and combustible fossil fuel resources. According to a study published in the American Journal of Clinical Nutrition, livestock in the US consume more than 7 times as much grain as the American population—enough grain to feed about 840 million people. The same study finds that roughly 25 kilocalories of fossil fuel energy are consumed for every 1 kilocalorie of meat protein produced, compared with a 2.2:1 ratio for corn. And producing 1 kg of animal protein requires 100 times more water than 1 kg of grain protein, in part because we have to take the water used to grow the animals’ food into account. You can read the full report for additional statistics, but you’ll find that on nearly every measure, raising livestock takes a lot more resources per calorie out than growing edible plants does.

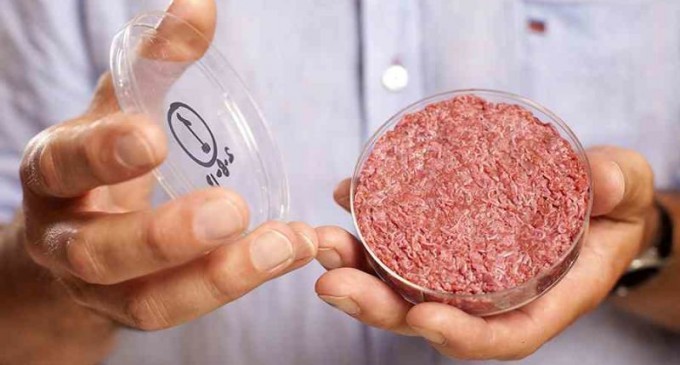

Cultured meat isn't just a theory, although it might sound a little like science fiction. In fact, it's already been done:

Two years ago, physiologist Mark Post of the University of Maastricht unveiled the world’s first cultured beef burger, assembled in his lab from thousands of individual strands of muscle tissue. It precipitated an international media blitz: Hundreds of news articles, radio podcasts, and prime-time TV minutes were devoted to Unveiling of The Burger. But as for the flavor? A bit lackluster, according to food scientist Hanni Rützler and journalist Josh Schonwald, the two chosen tasters. As NPR reported at the time:

“The texture, the mouthfeel has a feel like meat,” Schonwald put it. “The absence is … fat. It’s a leanness. But the bite feels like a conventional hamburger. It’s kind of an unnatural experience [without condiments].”

Rützler agreed the burger was edible, but not delectable. “It has quite some intense taste, it’s close to meat,” she said. “I thought it would be softer.”

Still, one can argue the demonstration was less about the meat’s flavor and more about what scientists had managed to accomplish. Over the course of three months, Post’s lab turned a handful of stem cells extracted from a cow’s shoulder into a patty consisting of 20,000 individual muscle fibers. Keeping those cells healthy, well-fed and contamination-free during their growth was no small feat — in fact, it’s something biomedical engineers in the artificial tissue business have been struggling to do for over a decade.But with a $300k price tag and a mediocre review, Post knew he had to do better. He’s spent the last two years refining the process, and I caught up with him over the phone to hear how it’s been going.

One of the big takeaways from the 2013 cultured burger demo was that meat just ain’t right without fat. So, Post’s lab is now culturing fatty tissue in addition to muscle fibers. Working out that process has taken some time. Until now, there hasn’t been a whole lot of scientific interest in culturing fat cells, and methods that did exist used chemicals we don’t really want to be eating.

“The original methodology to make fat cells from stem cells requires steroids, which are not wanted in food applications,” Post told me. “We had to redesign that and work with the biochemistry of the cell to figure out which stimuli we should use. We now have a bunch of natural components of fat that actually stimulate fat production.”

Right now, Post’s lab is culturing beef fat and muscle tissue separately, and mixing the two after the fact. In the future, Post imagines combining the two cell types in a co-culture. But first, there are a couple other burger basics the team is trying to improve on.

For one, Post would like to eliminate the use of animal products (stem cells aside, obviously) from the culturing process. In laboratories, cells are often grown using a fetal bovine serum extracted from unborn calves. But from a sustainability point of view, juicing a baby cow to grow a burger is less than ideal. It also doesn’t do much for cultured beef’s image as a cruelty-free product. And, while it may be an unlikely scenario, a disease-contaminated batch of fetal bovine serum could spell disaster. Better off, Post says, if we could work out an animal-free culture serum — one based on photosynthetic algae or cyanobacteria, perhaps.

Another technical issue Post’s team is trying to sort out how to boost cultured beef’s iron content. In muscle tissue, iron is found primarily inside an iron and oxygen-binding protein known as myoglobin. But because lab-grown meat lacks a circulatory system, it’s kept in a very high-oxygen environment, which has the unintended consequence of reducing cellular myoglobin expression. Less myoglobin means less iron, poorer nutritional content and a weaker flavor.

Once Post is satisfied with cultured beef version 2.0 — a fattier, more iron-rich and animal-free substance than its predecessor — he’ll start thinking about scaling up. Going from petri dishes to factories raises a host of new issues. For one, there’s that oxygen problem again: Without a circulatory system and blood vessels to shuttle O2 around, we can really only ever hope to grow thin sheets of meat. Post wouldn’t get into specifics about the technologies involved in scaling this process up, other than hinting that 3D printers and new types of scaffolding materials might be involved.

Wow!

We're really curious to see how this turns out. We can't imagine lab-created meat ever tasting like the real thing, but with science advancing so rapidly, who knows what could happen in just a few years?

Tell Us What You Think!

Article Source: Gizmodo

No way!